一、糖果浇注模具的基本概念

糖果浇注模具是一种用于形状多样的糖果生产的工具。它的主要功能是在糖果浇注过程中提供特定的形状和尺寸,适合制作各种糖果,如硬糖、巧克力、软糖等,广泛应用于糖果制造行业。这些模具一般由食品级材料制成,如金属,确保能在高温下安全使用。

二、设计与应用

多样化设计:

- 糖果浇注模具可以设计成各种形状,如水果、动物、节庆图案等。这种多样性使其能够满足不同消费者的需求,以及市场上的新潮流。

定制化生产:

- 制造商通常会根据市场需求和客户要求进行模具的定制设计。例如,某个节日可能需要特定的形状,而市场上流行的动漫角色又能带来新的设计需求。

材料选择:

- 金属糖果模具因其便于脱模、耐用以及优良的热传导性能,广泛应用于大规模生产。

三、功能与优势

高效生产:

- 糖果浇注模具有助于提高生产效率。通过成型快速脱模,能支持快速周转,尤其适用于大规模生产线。

一致性与质量控制:

- 高质量的模具能够确保糖果在形状和尺寸上的一致性,进而提升品牌形象和消费者满意度。

降低成本:

- 高耐用性的模具减少了频繁更换的需求,长期来看能显著降低生产成本。

易于清洁与维护:

- 大多数现代糖果模具设计考虑到了清洗的便利性。无论是使用高温蒸汽机还是普通清洗剂,模具的表面处理能确保快速卸妆,减少生产过程中的清洁时间。

四、朗盈模具的优势

朗盈模具作为一家专业设计和生产糖果模具的公司,其优势体现在多个方面:

高精度设计能力:

- 朗盈模具采用先进的技术,确保每个糖果模具在设计和制造上的高精度。这保证了模具能够精确符合客户的需求,达到完美的产品形状。

定制化服务:

- 朗盈模具能够根据客户的具体需求提供定制服务,无论是特殊形状的模具,还是独特的尺寸设计,都能快速响应,满足市场的多样化要求。

优质材料选择:

- 凭借严格的原材料选用标准,朗盈模具制作的模具不仅安全耐用,还在高温下表现优良,能够应对大规模生产的挑战。

创新研发能力:

- 朗盈模具持续进行技术创新,研发新型模具,致力于引领市场趋势,使客户在竞争激烈的市场中始终保持领先地位。

全面的技术支持:

- 在模具的使用过程中,朗盈模具提供全方位的技术支持,确保客户在生产中实现无缝对接,减少停机和损失。

五、糖果浇注模具在加工流程中的应用

在糖果生产过程中,糖果浇注模具与糖果浇注机密切配合,发挥重要作用:

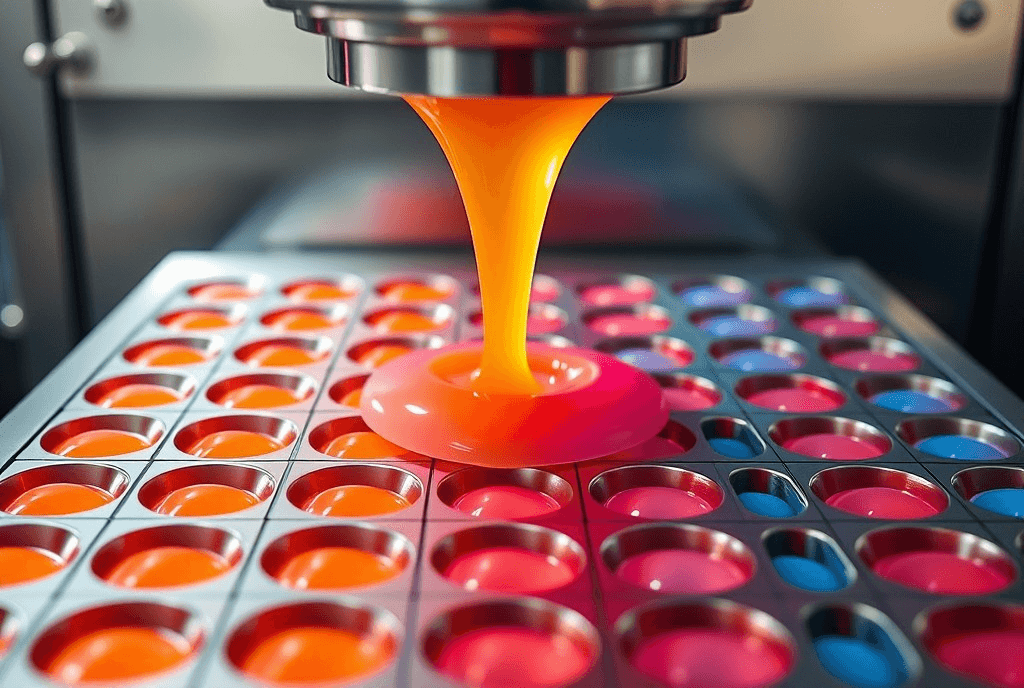

浇注环节:

- 糖果浇注机将预热的糖浆以适当的流量和速度均匀浇注到模具中,使其填满。

冷却与固化:

- 浇注后的糖浆在模具中冷却并固化,形成最终的糖果形状。这一过程需要控制模具的温度和环境,以确保糖果的质感和外观。

脱模与后处理:

- 一旦糖果固化,可以通过机械或者人工方式轻松脱模。此后,糖果会经过包装和其他后处理流程。

六、未来发展趋势

随着消费者对糖果的需求越来越多样,创新性的糖果浇注模具也在不断提升。例如,开发新型材料、引入数字技术、改进模具设计等,都将使得糖果的生产更具灵活性和效率。

结语

糖果浇注模具在现代糖果生产中扮演着不可或缺的角色。它们不仅提升了生产效率和产品质量,还为企业提供了灵活应对市场变化的机会。通过与朗盈模具的合作,企业能够充分利用高品质的模具和卓越的技术支持,在竞争日益激烈的市场中获得优势。无论是传统糖果还是新颖创意产品,糖果浇注模具都是推动行业发展的关键因素。