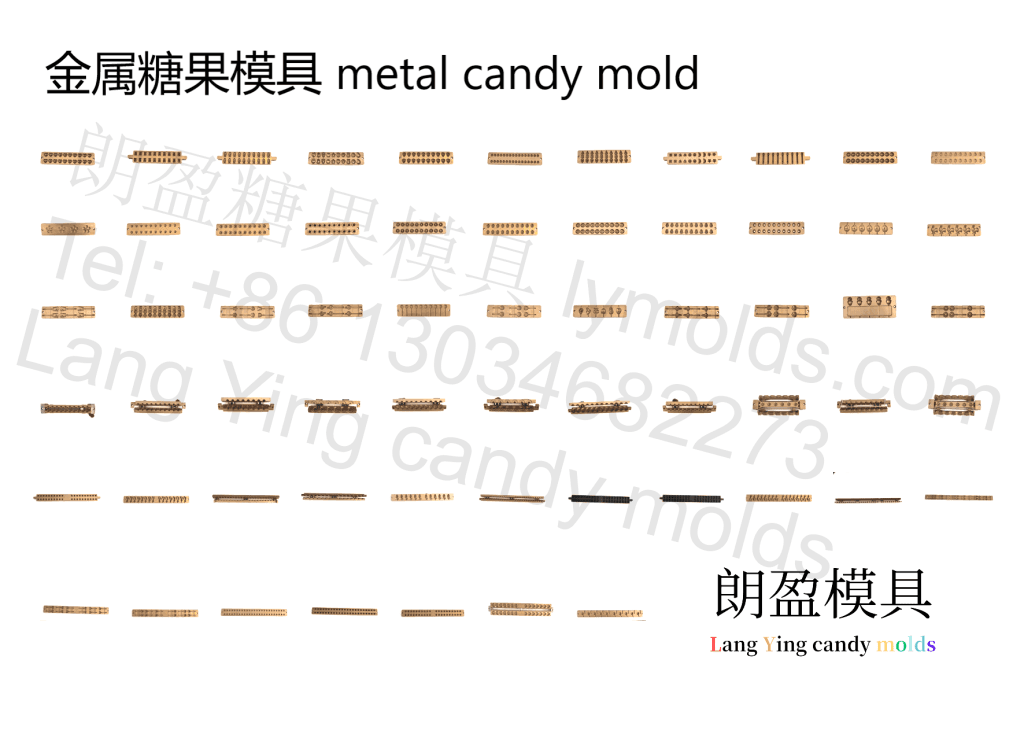

In commercial candy production, selecting the right molds not only determines production efficiency but also directly impacts the product’s appearance and manufacturing costs. For large-scale production lines, mold durability, precision, and food safety are crucial factors. This guide highlights the advantages of metal candy molds compared to silicone and plastic molds, with insights on how Lang Ying Molds excels in designing and producing high-quality candy molds to help businesses make better choices.

1. Durability of Metal Candy Molds

In commercial candy production, molds must endure frequent use and high-temperature operations. Metal candy molds stand out for their excellent durability and stability. They maintain their shape over time, even in high-demand environments. This makes metal candy molds the ideal choice for commercial production, as they reduce the need for frequent replacements, ultimately lowering production costs.

In comparison, silicone molds, while suitable for small-scale production, tend to lose their elasticity under heavy use, affecting the shape of the final product. Plastic molds, on the other hand, are more likely to deform under high temperatures and may become brittle with frequent use, increasing long-term costs. As a company that specializes in high-quality metal candy molds, Lang Ying Molds ensures that its products perform exceptionally well, even under frequent, high-intensity use.

2. Superior Heat Conduction for Increased Efficiency

Heat conduction is a key factor in candy production efficiency. Metal candy molds offer superior thermal conductivity, allowing heat to transfer quickly and evenly. This ensures that the candy syrup cools and solidifies rapidly, significantly reducing production times. For commercial production lines, this faster cooling process also minimizes product defects caused by uneven cooling.

In contrast, silicone molds, while heat-resistant, cool much slower due to their poor thermal conductivity, which lowers overall production speed. Plastic molds, when handling candies that require precise temperature control, provide even lower thermal conductivity. This can lead to temperature fluctuations that affect the quality of the candy. Lang Ying Molds’ metal candy molds help manufacturers greatly enhance production efficiency by ensuring every batch is of the highest quality.

3. Precision Molding for Product Consistency

In large-scale candy production, product consistency is essential for maintaining brand reputation and customer satisfaction. Metal candy molds are known for their high-precision molding capabilities. This ensures that candies maintain consistent shapes and sizes, even with frequent use. Such consistency is vital for maintaining a strong brand image and competitiveness in the market.

Silicone molds, due to their softness, can deform at high temperatures, and their stability decreases with frequent use, resulting in uneven candy sizes and shapes. Plastic molds, when exposed to high temperatures over time, may lose their precision, further affecting product consistency. By choosing Lang Ying Molds’ precision metal candy molds, manufacturers can ensure that every batch meets strict quality standards, enhancing the overall stability of the production line.

4. Food Safety and Ease of Cleaning

Strict hygiene standards in candy production require molds that are easy to clean and maintain food safety. Metal candy molds are corrosion-resistant and easy to sanitize, with smooth surfaces that prevent residue buildup. They can also withstand high-temperature disinfection, meeting the strict hygiene requirements of commercial production. Furthermore, metal candy molds are compatible with automated cleaning systems, reducing manual labor and increasing efficiency.

In contrast, silicone molds tend to absorb oils and syrup residues over time, making them harder to clean thoroughly. Plastic molds may suffer damage during high-temperature cleaning, and surface scratches make it difficult to clean them completely. Lang Ying Molds’ metal candy molds are designed to withstand frequent high-temperature cleaning, ensuring they meet food safety standards and offer reliable sanitation for candy manufacturers.

5. Versatility in Different Production Environments

Candy manufacturers often deal with various production processes, from high-temperature hard candy to low-temperature jelly production. Metal candy molds excel in their ability to adapt to different temperature environments. They maintain their structural stability in both high and low-temperature settings, making them ideal for a wide range of candy types.

Silicone molds, while flexible, may have difficulty with demolding in low-temperature environments, affecting the final product’s shape. Plastic molds, with their lower heat and cold resistance, are limited in their application across various temperature ranges. Lang Ying Molds’ metal candy molds, with their outstanding temperature adaptability, help manufacturers meet diverse production demands, improving overall production flexibility.

6. Long-Term Economic Benefits

While the initial cost of metal candy molds is higher than that of silicone or plastic molds, their long lifespan and durability make them a more cost-effective choice in the long run. Metal candy molds reduce the need for frequent replacements, minimizing production downtime and maintenance costs, making them ideal for large-scale production lines.

Silicone and plastic molds may have lower upfront costs, but their limited durability means they need to be replaced more often, leading to increased long-term production costs. Additionally, mold damage or deformation can lead to further production issues, causing additional losses. Lang Ying Molds’ high-quality metal candy molds help manufacturers lower their long-term costs by providing superior durability and ensuring a higher return on investment.

Conclusion

Choosing the right candy molds not only affects the appearance and quality of the candy but also has a direct impact on production efficiency and cost control. Metal candy molds offer superior durability, thermal conductivity, and food safety, making them the ideal choice for commercial production. By partnering with a professional mold supplier like Lang Ying Molds, businesses can improve production efficiency while ensuring that every batch meets the highest quality standards.

Whether the goal is to achieve consistent product quality or optimize production costs, metal candy molds remain the top choice for commercial candy production.