Hard candy is a popular traditional confectionery that enjoys widespread love from consumers around the globe due to its rich flavors and chewy texture. The production of high-quality hard candy relies heavily on high-quality candy molds. This article focuses on hard candy molds, specifically metal candy molds, and highlights the advantages and characteristics of a professional candy mold manufacturer—Langying Molds.

1. Overview of Hard Candy Molds

Hard candy molds are tools used to shape cooled syrup into various forms. The molds can be classified based on material, shape, and scale, offering a range of applications. Whether for home use or large-scale commercial production, selecting suitable candy molds is crucial for improving product quality.

2. Main Types of Hard Candy Molds

Hard candy molds can be categorized based on material, shape, and design form:

- Material Classification:

- Metal Molds: Made from aluminum alloy or stainless steel, these molds are high-temperature resistant and have good thermal conductivity, making them ideal for commercial production.

- Silicone Molds: Made from food-grade silicone, they are flexible and suitable for home DIY projects.

- Plastic Molds: Generally made from food-safe plastic, they have a lower production cost and are suitable for making simple candies.

- Shape Classification:

- Standard Shape Molds: Typically used for making classic hard candy shapes like circles, squares, and stars; they are suitable for most hard candy manufacturers.

- Custom Shape Molds: Offer personalized designs based on customer needs, enabling the production of unique candy shapes for holidays, celebrations, or corporate promotions.

- Multi-Cavity Molds: Allow for the production of multiple candies in a single mold, suitable for commercial production and enhancing efficiency.

- Design Form Classification:

- Flat Molds: These molds are generally used to create simpler hard candies with comparatively low heights, making them easy for batch production of standard shapes.

- 3D Molds: Designed with three-dimensional elements that can produce complex and visually appealing candies, such as shapes of animals or plants, attracting consumer attention and suitable for special occasions or themed candy production.

3. Advantages of Metal Candy Molds

Among various candy molds, metal candy molds stand out for their numerous advantages:

- Durability:

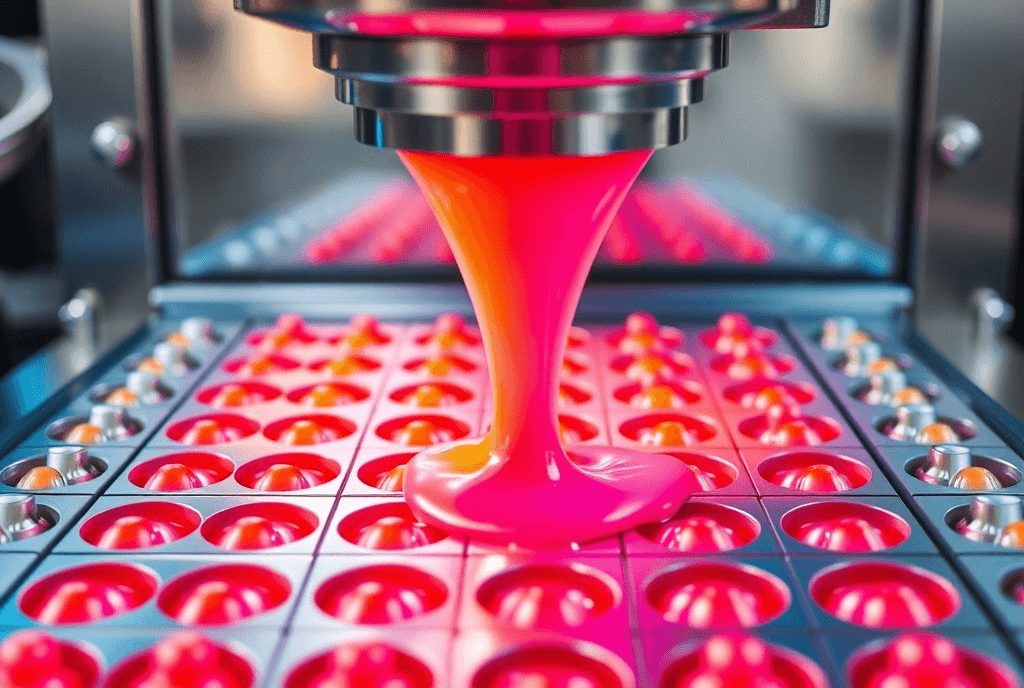

Metal molds are highly resistant to wear and tear, making them suitable for long-term use and high-intensity commercial environments. - Excellent Thermal Conductivity:

Metal materials have great thermal conductivity, allowing for quick and even heat distribution, which helps the syrup solidify rapidly, reducing production time and increasing efficiency. - Precision Forming Effect:

Metal molds typically create complex shapes and fine details, meeting high market demands for both appearance and taste, enhancing product competitiveness. - Ease of Cleaning and Maintenance:

The smooth surface of metal molds resists sticky sugar residues, making them easy to clean and maintain a hygienic production environment. - Suitable for Large-Scale Production:

Metal molds are ideal for large-scale commercial production, enabling rapid fulfillment of large orders and lowering unit production costs.

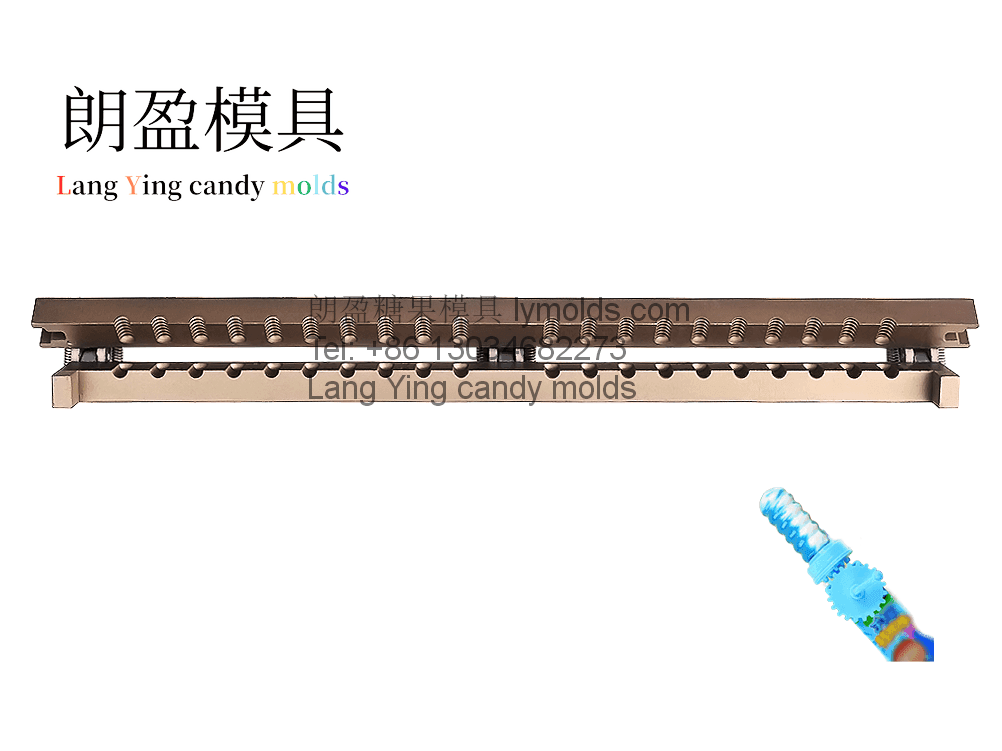

4. Company Profile of Langying Molds

Since its establishment, Langying Molds has focused on the design and production of candy molds and has become a leading specialist manufacturer in the industry. The core philosophy of the company is innovation and quality, dedicated to providing efficient, durable, and diverse candy mold solutions to customers. Langying Molds enjoys a good reputation in the industry, with professional design teams and advanced production technologies, especially excelling in metal candy molds.

5. Features of Langying Molds’ Products

- Diverse Product Line:

Langying Molds offers a wide range of candy molds, including metal, silicone, and plastic molds, to meet different customer needs. Particularly in the area of metal molds, Langying provides various designs and sizes to fit various hard candy production processes. - Customized Services:

Based on specific customer requirements, Langying Molds provides customization services, allowing tailored molds according to customer design drawings or product needs. - Continuous Technological Innovation:

Langying Molds consistently monitors market trends and emerging technologies, regularly updating its product line with the latest materials and processes to ensure that its products remain at the forefront of the industry. - Focus on Customer Experience:

Langying Molds values communication with customers and offers high-quality after-sales services to ensure any issues encountered during use are resolved promptly, enhancing customer satisfaction.

6. Conclusion

Hard candy molds are the key tools for making delicious hard candies, and metal candy molds, with their durability, excellent thermal conductivity, and precision forming capabilities, are the preferred choice for producing outstanding hard candies. Langying Molds leverages its professional design and manufacturing expertise to provide high-quality candy mold solutions. In the candy-making industry, whether for home use or large-scale production, choosing Langying Molds will significantly improve your candy-making efficiency and quality. With professional hard candy molds, you can easily create attractive and tasty hard candies that will win consumer favor.