With the rising awareness of health and the increasing demand for nutritional supplements, nutritional gummies have emerged as a more appealing choice for consumers. Starch-free production technology is redefining this market with superior hygiene standards and production efficiency. Langying Molds, a subsidiary of Ningbo Langying Machinery, stands out in this domain with its professional design and manufacturing of a diverse range of candy molds.

Advantages of Starch-Free Technology

The starch-free technology eliminates the use of traditional starch molds, simplifying the production process and significantly enhancing the hygiene and safety of products. Here are several key advantages of starch-free technology in the manufacturing of nutritional gummies:

- Higher Hygiene Standards

Traditional starch molds carry the risk of cross-contamination, particularly when producing gummies containing functional ingredients. Starch-free technology uses robust, stable molds, eliminating this risk. By removing the need for starch recovery and handling, the cleanliness of the production process is greatly enhanced, ensuring the purity and safety of every gummy produced.

- Increased Production Efficiency

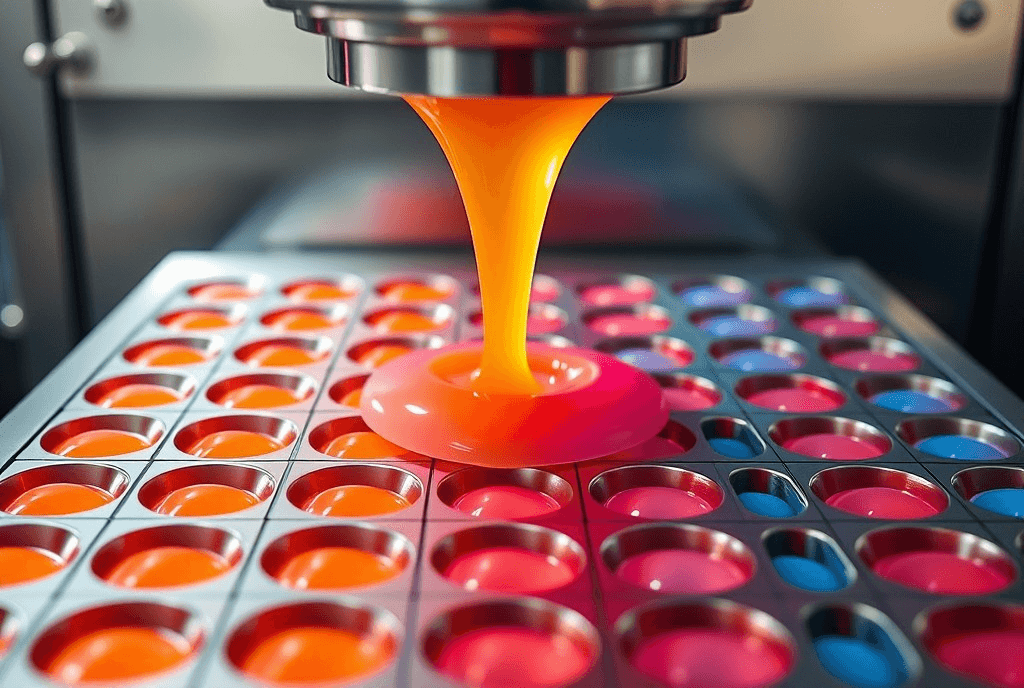

The implementation of starch-free technology drastically shortens the shaping and drying process of nutritional gummies. Traditional methods often require hours, or even up to 24 hours, for drying, while starch-free production can be completed in minutes. This means that production cycles are significantly reduced, allowing manufacturers to respond more rapidly to market demands and improving overall production capacity.

- Reduced Production Costs

The use of starch-free technology allows manufacturers to decrease their reliance on starch, reducing raw material costs. Additionally, the maintenance and cleaning of production equipment become more straightforward, resulting in lower labor costs and energy consumption, ultimately enhancing return on investment.

The Unique Strengths of Langying Molds

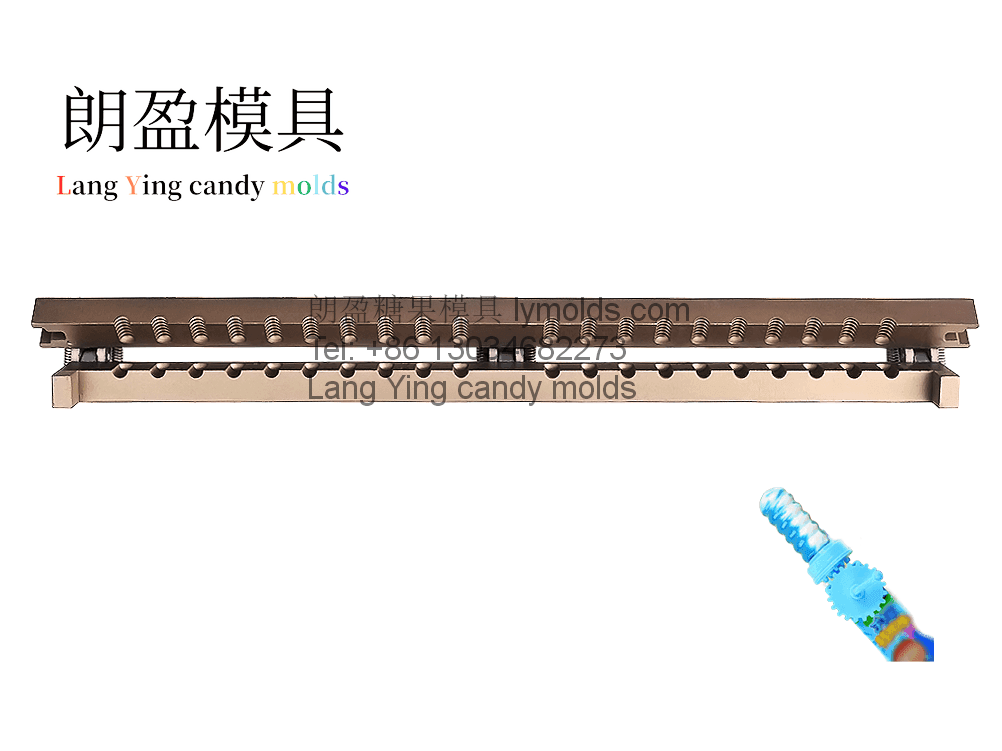

In the implementation of starch-free technology, Langying Molds provides a diverse range of mold products that enhance production flexibility and precision. The company mainly offers metal, silicone, and plastic candy molds, with metal molds displaying significant advantages:

- Superior Cooling Performance

Metal molds conduct heat better than silicone and plastic molds, allowing gummies to cool more quickly to the appropriate temperature. This rapid cooling process helps maintain the shape stability of the gummies, ensuring consistent size and appearance for each piece.

- Perfect Aesthetic Finish

The smooth surface of metal molds provides a higher gloss finish for the final product, making gummies more attractive to consumers. Furthermore, metal molds can create more complex shapes, meeting market demands for product diversity.

- Easier Cleaning and Maintenance

The material of metal molds allows for easier high-temperature sterilization and cleaning, preventing the growth of bacteria and contaminants. Compared to silicone and plastic molds, metal molds do not require the cumbersome starch cleanup process, significantly reducing maintenance costs.

Conclusion

Starch-free technology introduces a new concept in the production of nutritional gummies, enhancing product hygiene, production efficiency, and lowering costs. As a leader in this technology, Langying Molds brings significant changes to the industry with its high-quality metal molds. As consumer awareness of health products continues to grow, the market potential for nutritional gummies will expand. Choosing starch-free technology and professional molds will secure a competitive edge for manufacturers in the future.